Epoxy Wear Products

SCProbond™ A/CRC

SCProbond™ A/CRC is a premium trowelable, silicon carbide filled, abrasion and corrosion resistant wear compound designed for thick application on badly worn areas or known severe wear locations that see less than 95℃.

This material exhibits excellent resistance to the corrosive nature of chemicals such as sulfuric acid, nitric acid, ammonium hydroxide and sodium hydroxide while also providing protection from abrasive materials. SCProbond™ A/CRC is designed for processing environments commonly found in copper refineries, petrochemical applications, oil sands, chemical processing plants, power plants and other environments where corrosion and abrasion are an issue.

Epoxy Wear Products

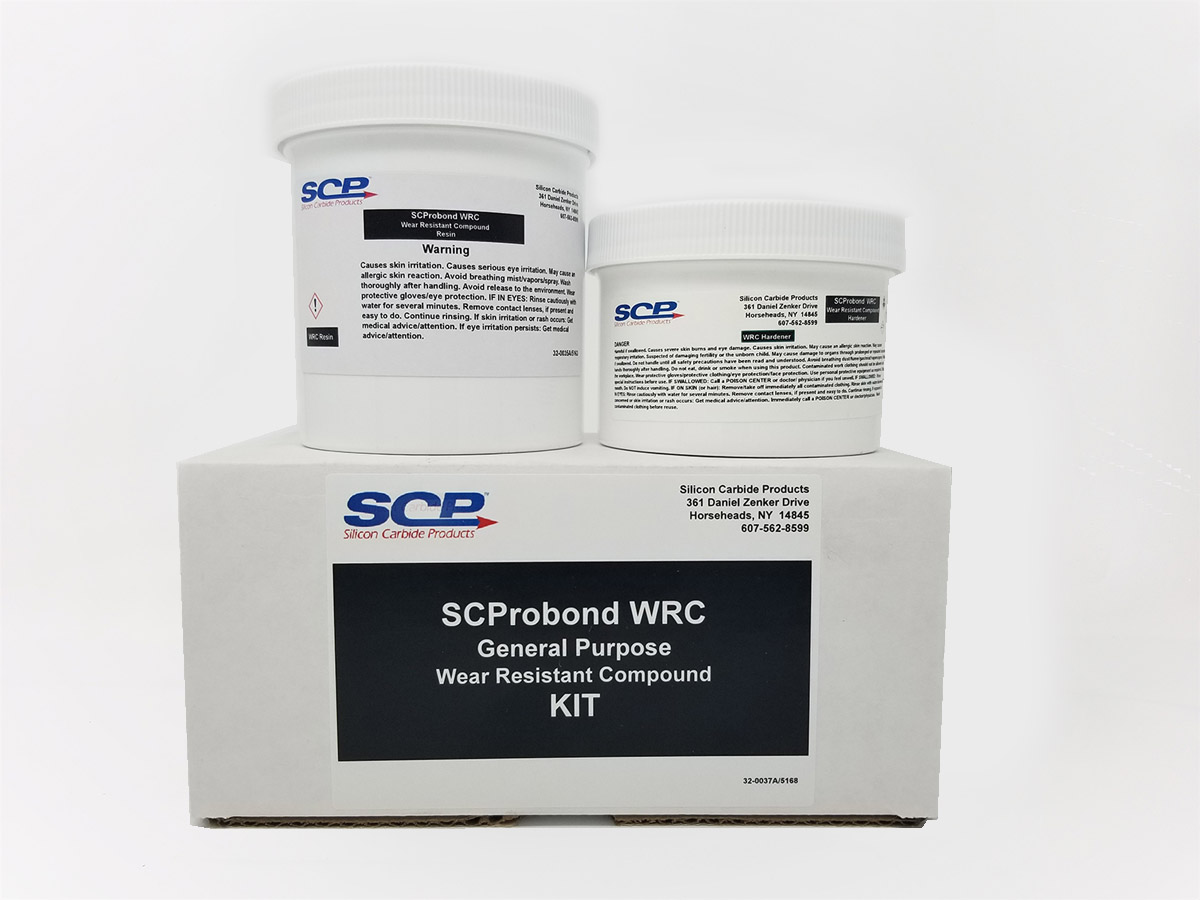

SCProbond™ WRC

SCProbond™ WRC is similar to our A/CRC, however this product is more of a general purpose abrasion resistant compound for wear protection formulated for areas that see less than 150℃ and where severe corrosion is not an issue.

SCProbond™ WRC is designed for use in pump casings, slurry lines, pipe elbows, pneumatic transport systems, chutes, cyclones, fans, coal breakers, pulverizers, coal heads, and other high wear areas.

SCProbond™ WRC Application Video

For additional protection against corrosive elements, check out our SCProbond™ A/CRC - Abrasion and Corrosion Resistant Compound

Designed for use in:

Pump Casings

Slurry Lines

Pipe Elbows

Coal Heads

Chutes

Cyclones

Air Separators